Interesting facts

about bulk goods

Discharge of your bulk material

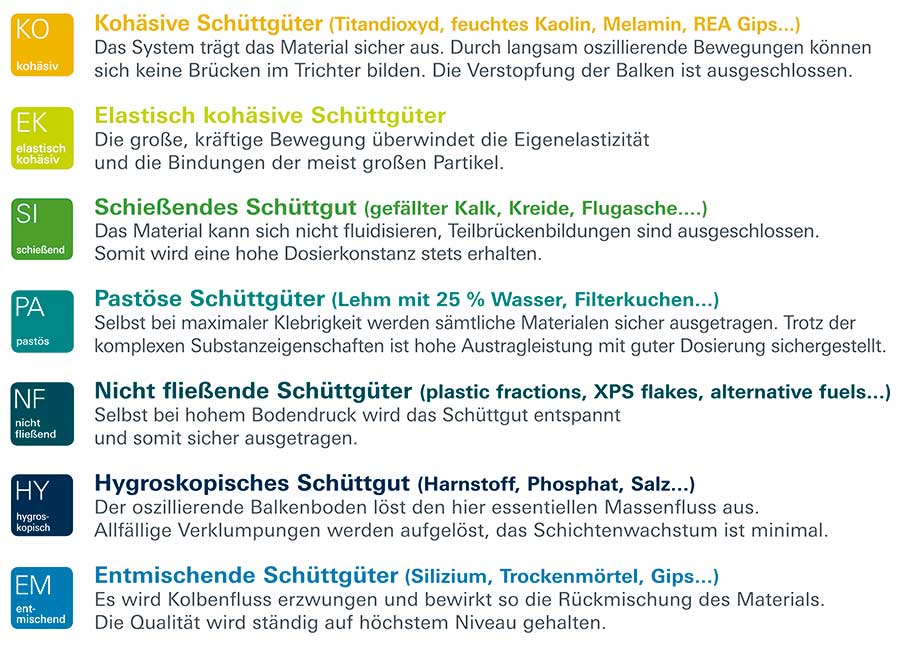

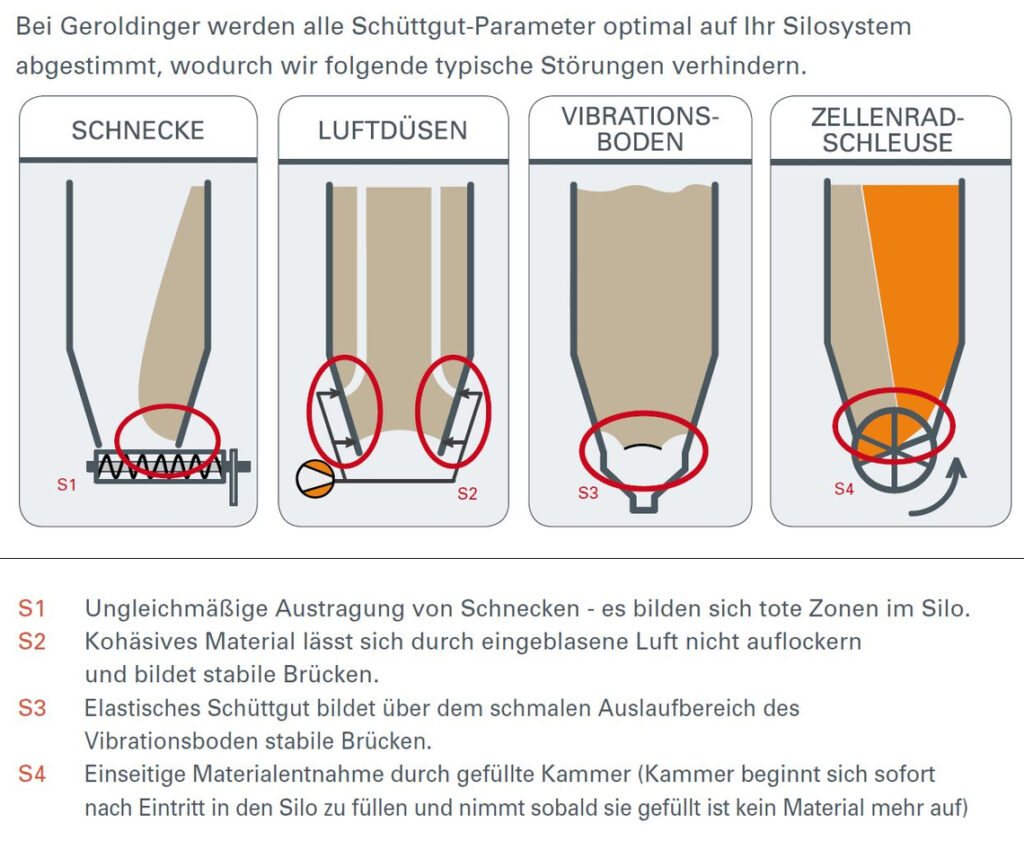

In many cases, supposedly unproblematic bulk goods turn out to be difficult to handle when used at a certain production step or a degree of automation.

Unsuitable discharge systems or incorrect silo geometry often cause problems. Serious difficulties can even lead to a complete shutdown of the production because processes can no longer be fed with material.

GEROLDINGER’s methods and expertise ensure safe discharge for all bulk goods. Learn more about our products here.

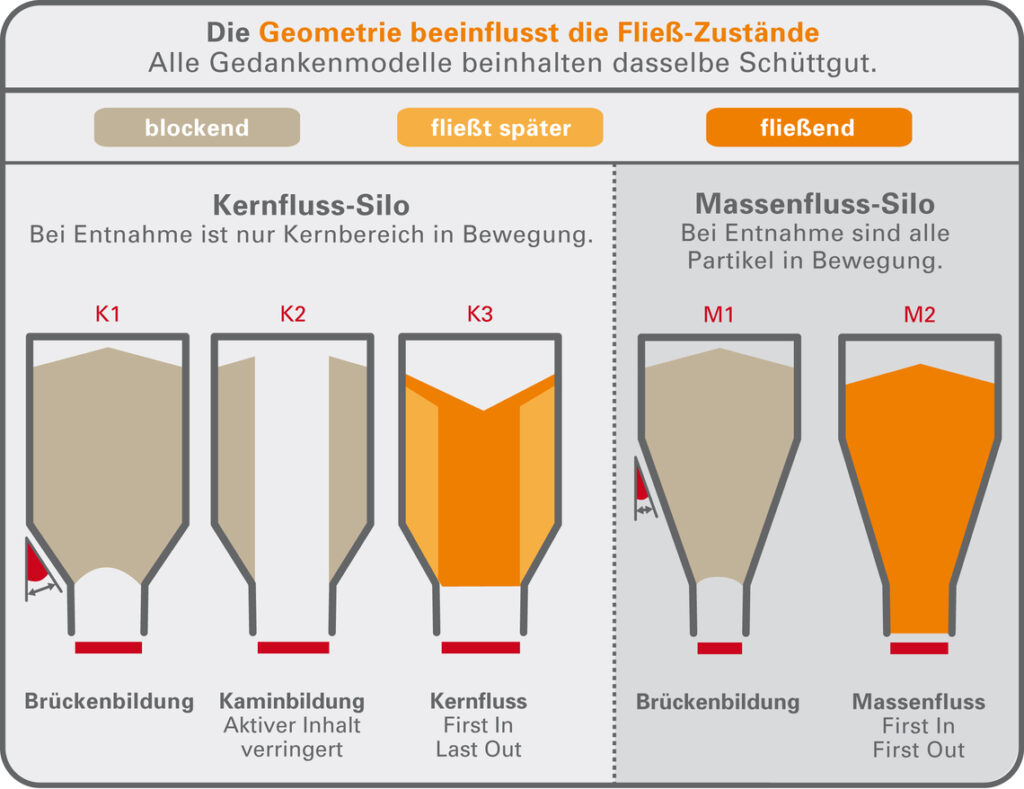

Mass flow – the key to preventing troubles inside the silo:

Mass flow is often addressed when storing bulk goods in silos. In fact, mass flow reduces all difficulties associated with storage, discharge, and batching of bulk solids. With mass flow, the entire contents of the silo are in motion. There are no dead zones = zones of bulk material at rest.

The opposite of mass flow is called core flow, which is a common problem.

With core flow, there are resting bulk material zones close to the wall of the silo. Only at the center of the silo the bulk material is in motion.

The correct silo geometry is a prerequisite for mass flow. To ensure mass flow, the bulk material must also be discharged simultaneously and uniformly over the entire discharge area (Oszillomat discharge system).

Tip: Don’t forget to include the properties of your bulk material. They will determine the optimum hopper inclination, which is essentially responsible for mass flow.

Guaranteeing safe discharge

Discharging the stored materials is the last step of a complicated process. Therefore, GEROLDINGER uses a clearly structured method to perform it reliably.

We start the process by analyzing the bulk material in our own lab to determine bulk density, particle size distribution and water content. The parameters are then compared with our extensive database. In doing so, GEROLDINGER uses and compares the lab results of simple hand tests, elaborate shear tests and all our already realized plants experience for similar bulk goods.

Today, there are about 1500 different samples available. Only the combination of the actual values of your test results and the experience gained through many years of practice, enables us to design the right plant – every time.

Are you experiencing issues with your bulk material or are you planning a project? Send us a sample of your material – and we will carry out a first analysis to find the right solution for you.